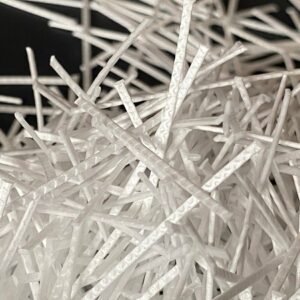

High-performance structural synthetic fibers

High-performance structural synthetic fibers are specifically designed for industrial flooring, road paving, and track slabs. These fibers are composed of a polypropylene and polyethylene blend and consist of four high-strength monofilaments linked side by side. This structure allows for more uniform mixing and easier dispersion. The fibers are characterized by high strength and excellent toughness, making them a viable alternative to traditional rebar mesh and steel fibers. These corrosion-resistant, fatigue-resistant, and impact-resistant high-strength fibers enhance the strength and durability of concrete.

Description

The unique design of concrete reinforcing Fibers makes them easier to disperse in concrete, reducing mixing time and improving construction efficiency. Compared to steel fibers, they have fewer exposure issues, making them easier to handle, which is why they are one of the favorite additives for flooring workers.

These fibers replace steel mesh and steel fibers in flooring, reducing the labor required for installation. Additionally, the amount of reinforcement fibers needed is only one-tenth that of steel fibers, reducing costs by 40%. Furthermore, these fibers are resistant to acid and alkali corrosion, reducing the need for maintenance.

The use of reinforcement fibers reduces wear on flooring equipment, decreases equipment maintenance, and lowers maintenance costs. A customer praised TopStar concrete reinforcing fibers, calling them the best flooring-specific fibers they have used, and at a very low cost.

Physical Properties

| Material | Polypropylene and polyethylene blend |

| Fiber size | diameter: 0.7mm; length: 35-58mm |

| Minimum tensile strength | >600MPa |

| Module | >9GPa |

| Elongation at break | ≤30% |

| Density | 0.92 g/cm3 |

| Acid and alkali resistance | excellent |

| Moisture content | ≤0.1% |

| Appearance | white, four-link wire, with embossed indentations on the surface |

user’s guidance

Dosage: Usually the dosage is 1.5-5.0kg/m3.

Length: The length should be 35-58mm. Depending on the floor thickness.

Mixing: It is advisable to add fibers to the concrete mixing station to ensure that the fibers are evenly dispersed.

Curing: The construction and curing process of the floor after adding fibers is exactly the same as the system without adding fibers.

Package

5kg per box, 500KG per pallet, volume per pallet 1.45m³