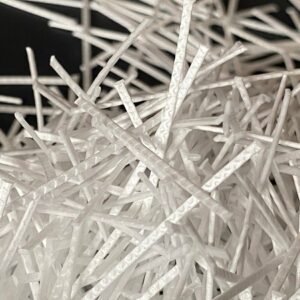

High-Strength Twist Wave Synthetic Fiber

High-strength twist wave synthetic fiber is specially designed for industrial use. It is a blend of polypropylene and polyethylene, and has the advantages of high strength and toughness. It can replace traditional steel mesh and steel fiber. This high-strength fiber with corrosion resistance, fatigue resistance and impact resistance enhances the strength and durability of concrete.

Description

How do concrete reinforcing Fibers enable industrial flooring to bear loads without being damaged?

More than 40,000 reinforcement fibers can be incorporated into 1 cubic meter of concrete. These fibers form a three-dimensional network within the concrete through mixing, creating a random support structure. This three-dimensional, randomly oriented dispersion is uniformly distributed among the aggregates and cement. The specially designed industrial flooring reinforcement fibers come in two types: four-strand and twisted spiral fibers. This design makes the fibers function like a mesh, firmly linking the entire industrial flooring concrete together. The support provided by the reinforcement fibers forms an internal skeletal structure within the concrete, significantly enhancing its impact resistance and fatigue resistance. Additionally, the reinforcement fibers make the concrete more resilient. As a result, whether the industrial flooring is used for storing heavy machinery or the logistics flooring for storing goods, whether it’s factory trucks or operational machinery from logistics companies, the fiber-reinforced flooring will not be damaged.

Physical Properties

| Material | Polypropylene and polyethylene blend |

| Fiber size | diameter: 0.5mm; length: 40-50mm |

| Minimum tensile strength | >600MPa |

| Module | >9GPa |

| Elongation at break | ≤30% |

| Density | 0.92 g/cm3 |

| Acid and alkali resistance | excellent |

| Moisture content | ≤0.1% |

| Appearance | Twisted synthetic coarse fiber |

user’s guidance

Dosage: Usually the dosage is 1.5-10kg/m3.

Length: The length should be 35-58mm. Depending on the floor thickness.

Mixing: It is advisable to add fibers to the concrete mixing station to ensure that the fibers are evenly dispersed.

Curing: The construction and curing process of the floor after adding fibers is exactly the same as the system without adding fibers.

Package

1 kg per small bag, 10 kg per large bag, volume of one ton 6.8m³, no pallet